|

| Slump |

Cause:

Printing process operating in environmental conditions outside recommended range.Action:

Installation temperature control module to regulate temperature and humidity within printer.

|

| Bleeding |

Cause:

Poor gasket between PCB and stencil, PCB support, squeegee pressure high, poor stencil or cleanlinessAction:

Ensure stencil aperture size is smaller than pads on PCB, improve PCB support,reduce squeegee pressure, check stencil for damage.

|

| Bridging |

Cause:

Stencil tension low, PCB support insufficient, poor cleanliness, poor paste qualityAction:

Correct stencil tension, cleanliness, improve PCB support and verify paste quality

|

| Paste in holes |

Cause:

Misprinted PCB, dirty PCBAction:

Fully clean PCB

|

| Peaking |

Cause:

Stencil process speed too high, stencil condition/cleanliness or aperture damageAction:

Modify PCB separation speed, check stencil

|

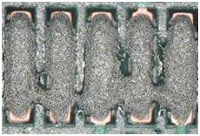

| Scooping |

Cause:

Squeegee pressure too high, stencil damaged or oversized aperturesAction:

Optimize squeegee pressure, redesign stencil apertures to reduce size

|

| Mis-alignment |

Cause:

Printer alignment error, PCB shrink or stretch, insufficient PCB support.Action:

Verify PCB to stencil alignment, fiducial marks are flat and well positioned

.jpg) |

| Incomplete Print |

Cause:

Blocked stencil aperatures, squeege pressure low, paste too cold or not well mixedAction:

Check paste, clean stencil, and adjust pressure

0 Comments